Mechanical Division

The Fantini Group Mechanical Division has been involved in several of the collaboration projects with National and International Scientific Research Bodies, such as ENEA (Italian National Agency for New Technologies, Energy and Sustainable Economic Development), the National Nuclear Physics Institute, EFDA (European Fusion Development Agency), IPP (Max Planck Institute of Plasma Physics). This type of project involves designing equipment and devices for use with experimental apparatus and machines that requiring a high degree of accuracy and complexity.

The Fantini Group Mechanical Division has been involved in several of the collaboration projects with National and International Scientific Research Bodies, such as ENEA (Italian National Agency for New Technologies, Energy and Sustainable Economic Development), the National Nuclear Physics Institute, EFDA (European Fusion Development Agency), IPP (Max Planck Institute of Plasma Physics). This type of project involves designing equipment and devices for use with experimental apparatus and machines that requiring a high degree of accuracy and complexity.

Fantini SpA and Eli Beamlines

Together for a wide field project

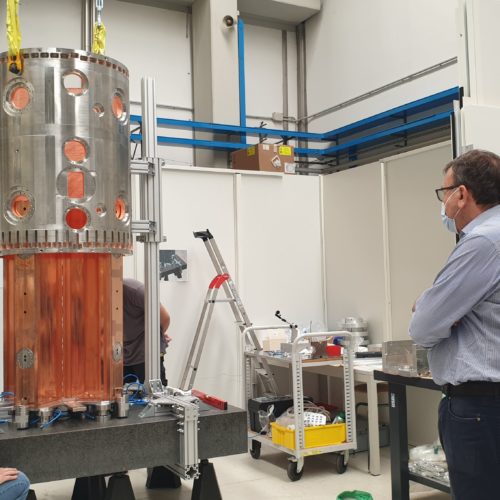

ELI Beamlines, the European laser research facility located in Czech Republic and installing the world’s most intense laser systems, worked with our company Fantini S.p.A. to deliver the six very large experimental vacuum chamber. This will be extremely relevant in fields of physics and materials science, in biomedical research and in laboratory astrophysics too. From 20 years our Big Science Division works in this area and our task consists in the execution of many Italian and international research projects, supplying with scientific apparatus and equipment. In this specific project, we worked to build the Vacuum Chambers necessary for the laser-based experiments in our Italian factory. The chambers are going to be one of the main appliances in the ELI’s scientific infrastructure in Czech Republic.

Since we are firmly convinced of the importance to contribute for enhancing projects like this, we are proud of this collaboration and the result achieved, aware of the relevance that this project has on a scientific and technological level.

We thank you for the trust you have always shown us and for the goals we achieve together every day.

Enjoy the view!

Case History: Projects with INFN

-

OPERA

Design and manufacture of various pieces of equipment and components on behalf of theNational Nuclear Physics Institute for use on the OPERA experiment, and installed at theGran Sasso underground laboratories. The following items were supplied:

- machine sheet metal panelling on the two spectrometers

- mounting structures for spectrometers

- copper bars for the upper and lower spectrometer windings

- lower and upper heat exchangers for cooling the copper windings

- stiffening and alignment beams for the spectrometers

- N. 124 semi-walls for housing the detector elements

- slower and upper semi-wall suspension support systems

Specifications

The OPERA experiment is designed to detect nm-nt oscillations in the neutrino beam generated at the CERN laboratories and captured at the Gran Sasso National Laboratories by means of “brick” detectors mounted in the semi-walls positioned between the magnets.

The detectors are in the form of “bricks” consisting of several alternating layers of photographic plates and emulsion sheets.

By studying any traces that may be produced on the photographic plate, the researchers hope to make progress in defining the mass of neutrinos. -

NA62

The NA62 experiment is currently under preparation by an International consortium involving INFN, CERN, Mainz, Triumf, Sofia, Mexico, JINR Dubna, IHEP Protvino, INR Moscow, Bern, Birmingham, Fairfax, SLAC and Merced.

The purpose of the experiment is the measurement of the rate of the ultra-rare decay K⁺→ π⁺ ν ν for a Standard Model determinant test, in order to determine the CKM matrix element |V td| with a precision of better than 10%.

One of the main factors contributing to the background is the K⁺→π⁺π° decays with the two undetected π° decay photons.

The experiment involves a hermetic photon veto system up to 50 mrad consisting of the existing calorimeter, small angle counters and a system of 12 counter (Anti) rings arranged along the decay tube at intervals of approximately 6 metres.Each ring contains blocks of lead glass fitted with multipliers (between 160 and 256, depending on the diameter of the ring), which must operate in a vacuum. Suitable flanges, with vacuum sealed feedthrough connectors, allow the high voltage supply to the phototubes, the output signals from the phototubes and the fibre optic cables for the luminous calibration pulses to pass.

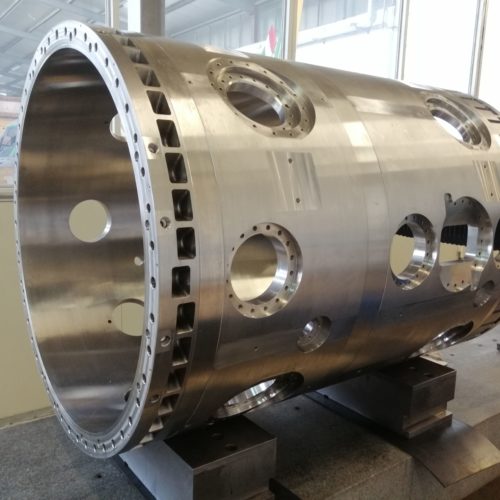

Fantini supplied the first 5 Vacuum Tubes (with the exception of the internal instrumentation) complete with lifting and rotation equipment. There are currently 4 more tubes with a greater diameter in production; these will be used to house larger numbers of lead glass blocks fitted with photomultipliers.

The structure of the ANTI used for the experiment NA62 consists of vacuum tubes that must maintain the geometrical position of the crystals. In order to guarantee low loss levels, the tubes are subject to hi-tech test processes at every stage of the manufacturing cycle, with particular focus on the choice of materials, the welding procedures and the high quality of the mechanical machining processes.

-

KLOE 2

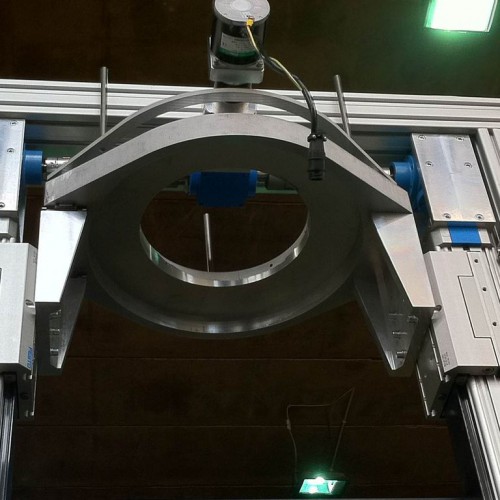

The concept of the cylindrical GEM detector was tested for the first time using a small prototype (radius 7 cm, length 24 cm) ( 22).

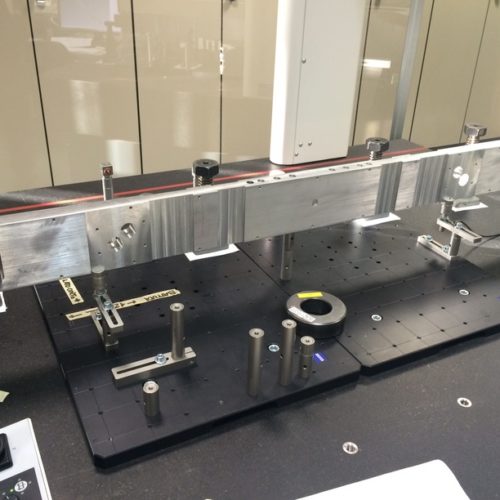

The positive results obtained with the prototype opened up the way to the construction of a full-sized prototype for the first layer of the Inner Tracker (IT). From this point onwards, the R&D activities for the finished version of the detector have focused on three elements: construction and test of a full-sized prototype cylindrical GEM detector; a detailed study of the XV reading unit based on dedicated small plane chambers for reasons of simplicity and cost; the realization of large GEM sheets based on new single mask technology.Fantini contributed to the final assembly of a CGEM layer , which was prepared using the Vertical Insertion System (VIS), a tool that permits the cylindrical electrodes to be inserted easily and safely, one at a time. The system has been designed to allow the cylindrical electrodes to be aligned precisely along the vertical axis.

The bottom electrode is fixed in place whereas the higher one is moved slightly downwards by a manual stepped motor coupled to a gear box. The operation is carried out with the assistance of three small web-cams positioned 120° apart around the top of the cylindrical electrode, in order to monitor the radial distance between the electrodes (typically 2-3 mm).

The assembled equipment can be rotated up and down in order to seal both sides. -

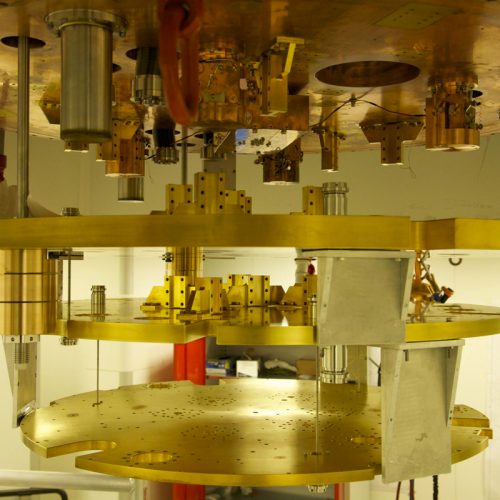

CUORE

Electrolytic copper components for the cryostat core used to create the “ultra-cold” conditions necessary for the CUORE neutrinic experiment.

The CUORE experiment is the result of a collaboration between thirty scientific and research institutes in Italy, USA, China, Spain and France and is the National Nuclear Physics Laboratory’s (INFN) buried deep under Gran Sasso, where the enormous mass of the mountain completely shields out all traces of cosmic radiation. The internal volume of the experiment is equivalent to 1 cubic metre and it is carried out at a stable temperature of 6 millikelvin (-273.144°C), i.e. just 6 thousandths of a degree above absolute zero (-273.15°C): this is, to all intents and purposes, the “coldest cubic metre in the Universe”.

The purpose of the CUORE experiment is to create the conditions for observing the extremely “neutrinoless double beta decay event”, which is necessary for determining the mass of neutrinos and, more broadly, to investigate the asymmetry between matter and anti-matter in the Universe.

The INFN has commissioned Fantini Sud to produce the NOSV electrolytic copper radiation detectors (tellurium oxide crystals), support plate, the associated upper and lower shields and the various separation and fastening components.

The semi-finished electrolytic copper products were reworked externally and internally to extremely strict mechanical tolerances, in as short a time as possible (in order to reduce the exposure of the material to environmental radiation), in absolutely clean conditions and using specific tools and lubricants (pure olive oil) in order to eliminate all risks of contamination to the finished components.

The production cycle for these components was subjected to the highest level quality control process. -

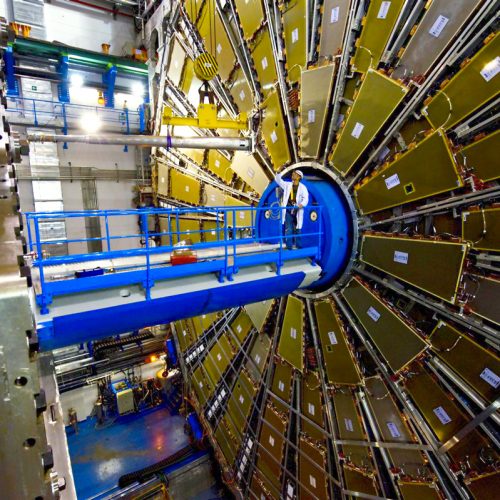

ATLAS

ATLAS experiment studies the head-on collisions of protons produced by LHC (Large Hadron Collider) at CERN in Geneva, to luminosity (1034) and energy beam (14 TeV) record values which will come through next steps.

The ATLAS assembly has a shell structure made up of several detection types placed around beam axes with cylindrical symmetry.

Each detector has a peculiarity skill and generally it can show a specific particle family or type.

Near interaction vertex there is the charged particles tracking then the electromagnetic and hadronic calorimeters and lastly there is the muon spectrometer which has also the task to give first level trigger for all the event with muon at the end state.

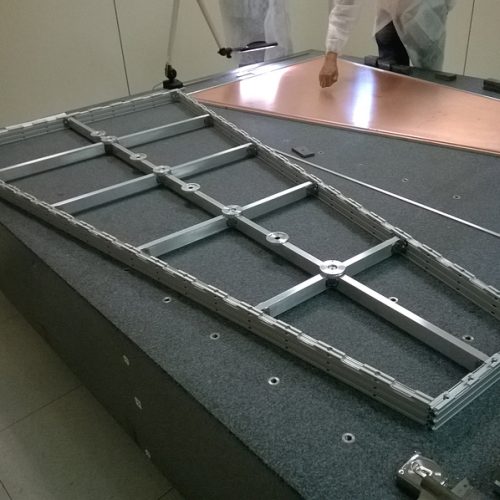

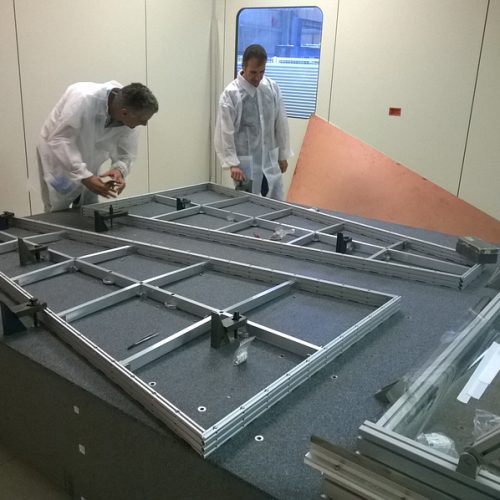

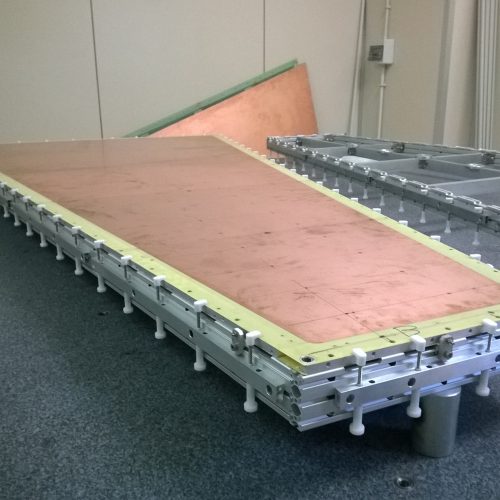

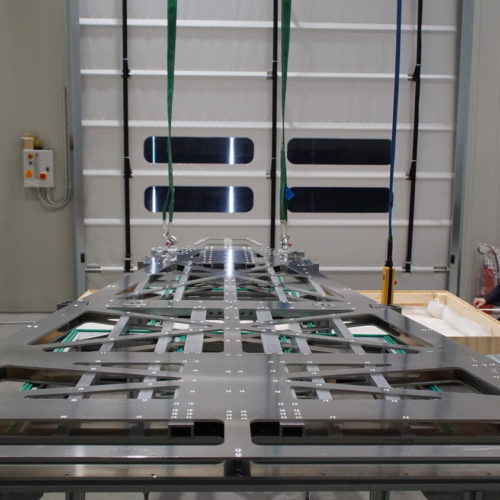

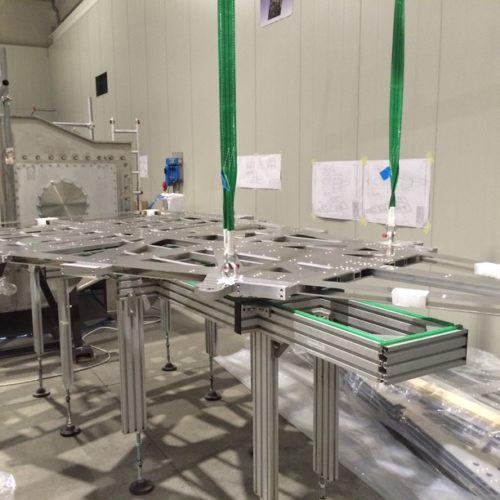

Fantini has supplied the components to n.3 Stiff_Frames realization composing the equipment for Micromegas chamber Drift panel construction to Small Wheel Upgrade project of ATLAS at CERN in Geneva.

Component mechanic manufacturing made by Fantini have enabled to reach the relevant project flatness specification of 100 micros. The Stiff_Frames assembly was made by INFN staff in Frascati National Laboratory clean room.

-

ELI - Extreme Light Infrastructure

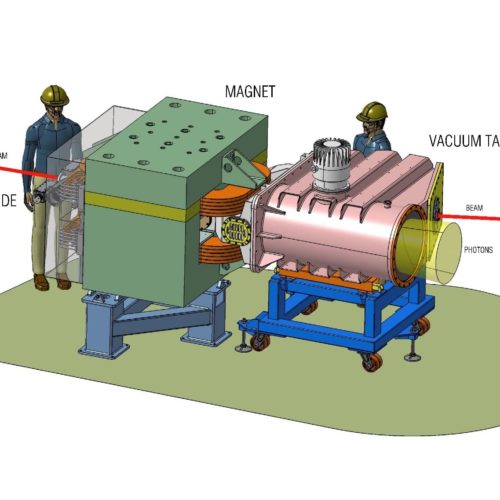

Magurele site ( Romania) will host a huge intensity and power laser (10 PW) with an intensity of 10231024 W/cm2 and a gamma ray source made by back-scattering Compton. The applications are about nuclear experiments in nuclear physics, photonuclear reaction, exotic nuclear physics and astrophysics.

Italy with CNR, INFN and Trieste synchrotron take part to the initiative since first steps and now is on first group of ELI members country with Romania, Czech Republic, Hungary, Germany and Great Britain. Particularly INFN coordinates Euro Gamma-S consortium which involves 12 partners among European institute and company to the realization of high intensity gamma source in Romania. INFN also collaborates with ELI-Beamlines about proton secondary source production to medical aim (ELI-MED).

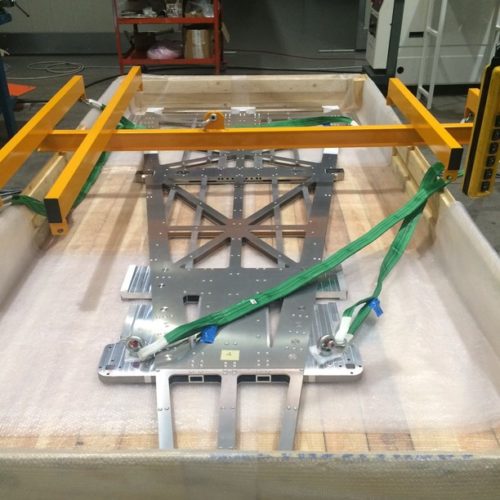

Fantini has contributed to experiment by providing several mechanical component types for ELI-NP GAMMA BEAM SYSTEM M1, M2, M3, modules.

Supply has been on a first lot of (n.6) Podestal support with relevant joining and focusing mechanics.

Furthermore set wheels to module handling were made; relatively to module handling company has made lift equipment even.

As a follow-up to this first supply step, supports for magnetic elements, vacuum chambers and particle beam diagnostic element were made.

Also the second supply lot, allocated to INFN Ferrara Section, has been on (n.4) Pedestal Support with relevant joining and focusing mechanics.

-

ESS - European Spallation Source

The new facility ESS (European Spallation Source) is in construction phase at Lund, in Sweden.

It is a particle accelerator which will allow analysis, characterization and material testing (metal or not) using neutron spectroscopic techniques with very high flux.

The new facility is considered strategic to keep Europe leadership in the innovative material research and development about for the manufacturing, pharmaceutical, chemical, energetic industrial sector application.In this context, the Nuclear Physics National Institute (INFN) is seeing to the design and realizing several parts of not superconducting accelerator: proton source, Radio Frequency Quadrupole and Drift Tube Linac.

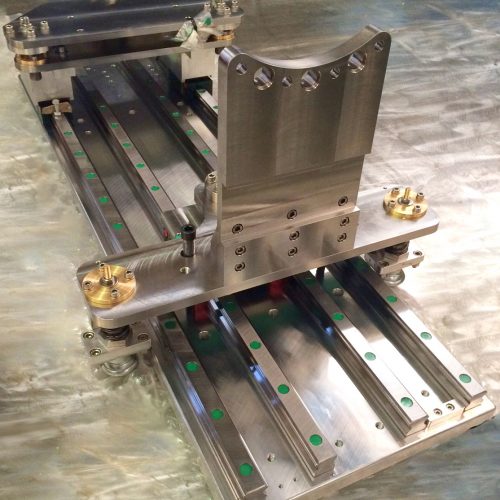

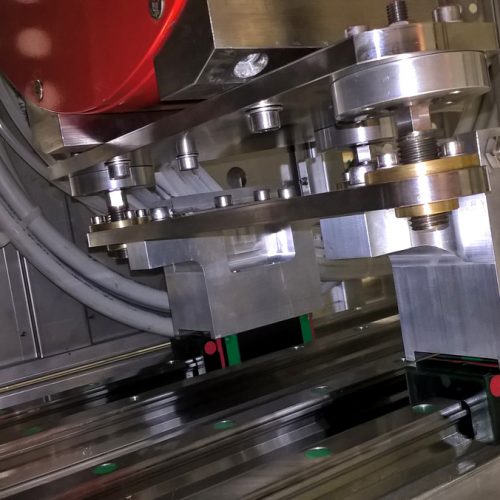

Throughout next engineering step INFN will extend its contribution even to superconducting cavity of accelerator high energy section.Fantini Sud has realized for INFN generator handling and accurately align mechanism (very high voltage fuelling) which is part of proton source.

Mechanism can balance generator weight exactly to help alignment with other source parts and it is installed in a shielding cubicle suitable to huge voltage defense.

The chassis architectural shape has even the aim to simplify and speed up the operator control, alignment and handling operations in order to improve radioprotection.

The chassis is made of aluminum alloy and stainless steel while generator connecting flange is of pure iron (ARMCO alloy). -

PMQ CAMERA FOR THE ELIMED RADIO-THERAPY DEVICE

Description of supplier

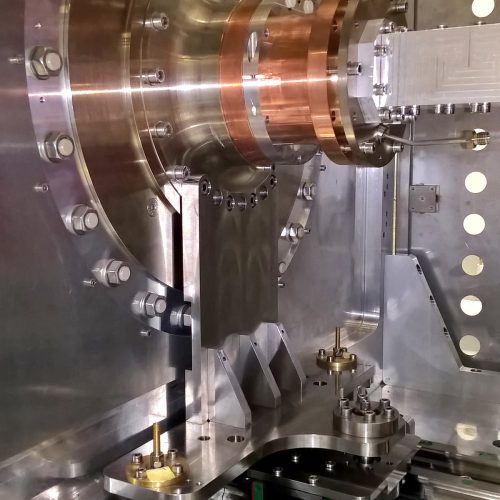

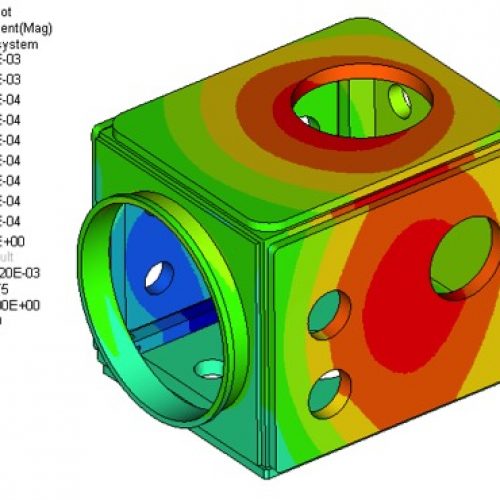

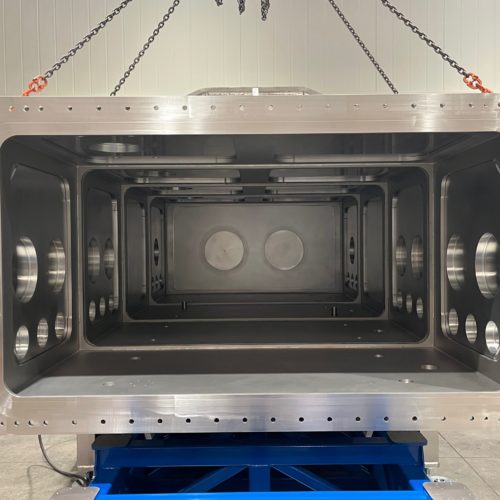

Working to an order from the National Institute of Nuclear Physics – South Laboratories of Catania – a high vacuum room has been constructed to house magnetic diverters for supplying the ELIMED Oncological Radiotherapy Laboratory (Hadron therapy) at the ELIBeams Research Institute in Prague (Czech Republic). The chamber – with a volume of 900 litres- is made of a stainless steel and aluminium alloy, and operates under high vacuum (1 x 10-6 mbar) due to a turbo-molecular pump. In addition to sealing devices, the chamber also houses the precision servo mechanisms needed for positioning and retracting the diverting magnets that gather, deflect, and focus a small bundle of particles generated in another vacuum-connected chamber (Elimaia Interaction, which is also built by Fantini Sud on behalf of ELIBeams) at a new laboratory for ultra-high energy physics.Trial description

The ELIMAIA trial is one of the latest trends in research on interactions between matter and the high energies generated by some of the most powerful pulsed laser sources ever built. The interactions between the material and the laser beam allow the ELIMED device to focus on a bundle of extremely thin but powerful charged particles that can be conveyed with great precision and selectivity into delicate and sensitive areas of the human body (e.g. brain and nerve tissues) to treat oncological masses. -

PADME

Description of the supply

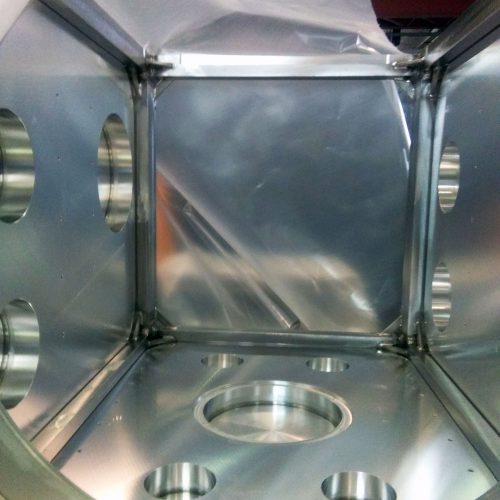

For the National Institute of Nuclear Physics, the following equipment was developed for the Padme experiment and installed at the INFN National Laboratories of Frascati. The supply concerned the realization of the ” VACUUM TANK ” of the PADME experiment and consists of n. 1 vacuum chamber of about 1 m3 of volume, made of two parts rigidly coupled together to form a single structure with a mechanical consistency suitable for bearing at external atmospheric pressure. Mechanical supports suitable to manage the room during assembly, testing and installation and lifting equipment to make the use of the bridge crane during transport phases. The supply was managed in compliance with the Machinery Directive 2006/42 / EC and in compliance with ISO 9001 quality management and in the first phase of the order a technical report was produced containing the calculations and the structural checks of the entire structure (rooms and supports ) according to current regulations.Description of experiment

The Padme experiment works thanks to a small but extremely precise measuring device, able to observe the production of dark photons in collisions of electrons and anti-electrons, called positrons. The experiment is installed in the experimental room of the test facility (BTF) of the LNF linear accelerator which accelerates positrons by “shooting” them on a diamond target. Interacting with atomic electrons, the positrons could produce “dark photons” together with a visible photon. To work, the experiment needs a magnetic field developed by a magnet made at CERN Super-Proto-Synchrotron. The PADME calorimeter is composed of about 600 inorganic sparkling crystals and will provide a precise measurement of the characteristics of the visible photon from which it is possible to extract valuable information on the existence and mass of the dark photon. PADME is an international collaboration involving researchers from the MTA Atomki institute in Debrecen, Hungary, where experiments have already been carried out on the “dark photon” and the University of Sofia, Bulgaria, which will take care of the scintillating bar detectors. They are also members of the Cornell University collaboration, Iowa University and William and Mary College. -

Mu2E

Description of the supply

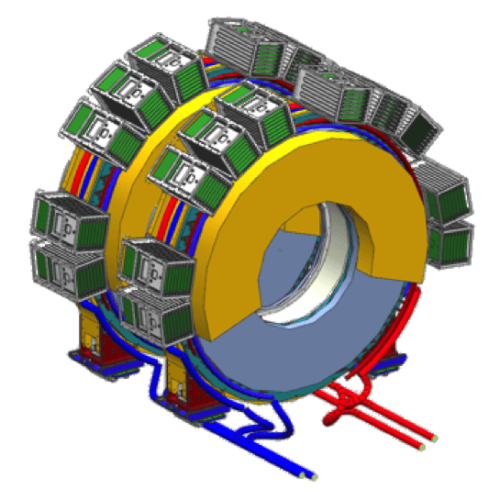

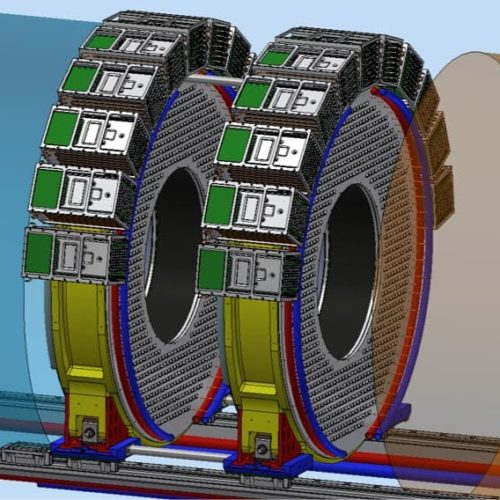

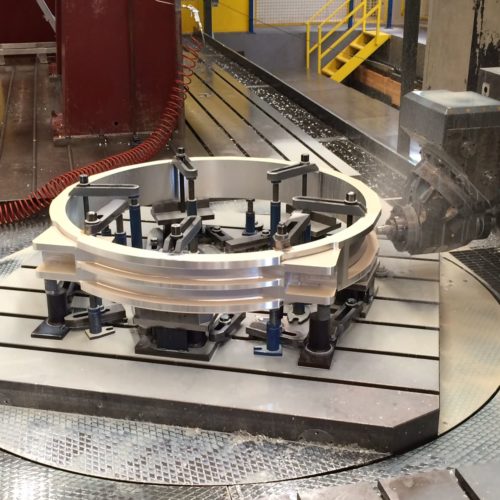

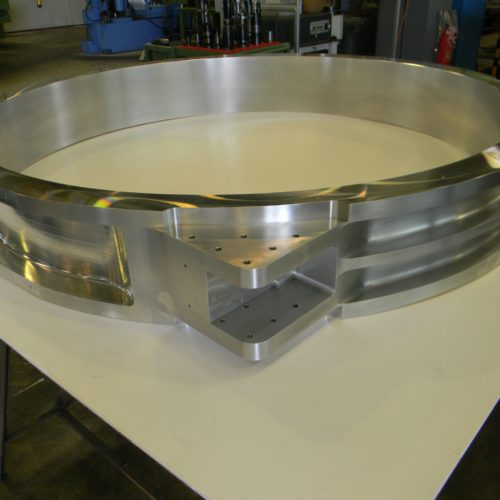

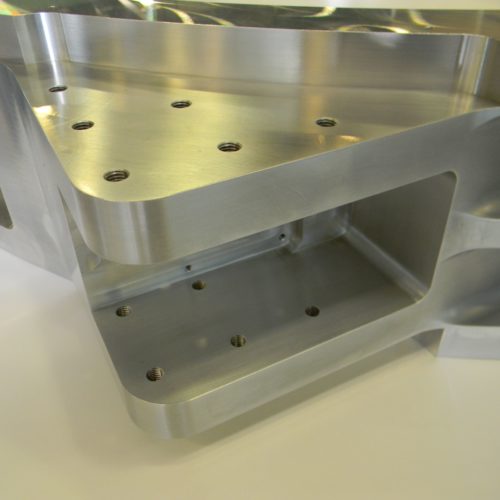

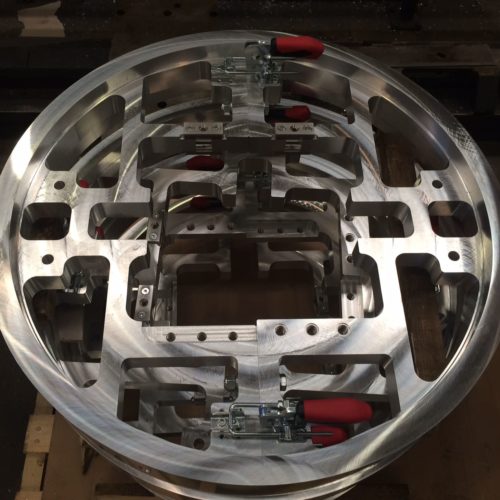

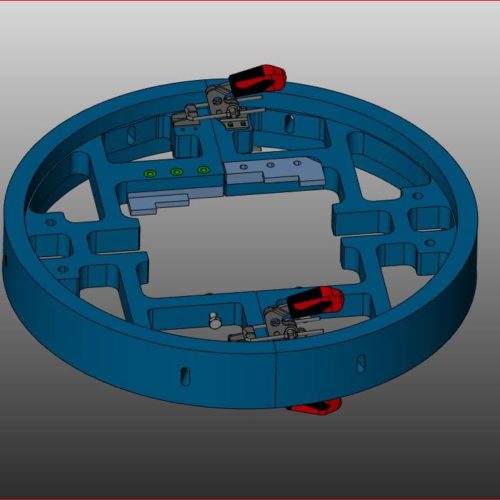

For the National Institute of Nuclear Physics, the following equipment was designed for the Mu2e experiment. The supply concerned the realization of the mechanical structure of the calorimeter, a component made starting from a sheet of high thickness of aluminum which, after appropriate water cutting, was machined on a numerically controlled machine tool. The supply was managed in compliance with the standards requested by the client.Description of experiment

The calorimeter of the Mu2e experiment is constructed from 1348 sparkling crystals divided into two 1.60 m high “donuts” and optimized to identify electrons, probably the most famous among the particles. Mu2e looks for a process of converting a muon (a sort of elder brother of the electron) into an electron. In the electron’s travel inside the calorimeter crystals, photons are produced in proportion to the energy of the starting electron, until the electron stops inside the detector itself. That is, the greater the energy released into the crystal, the greater is its scintillation light. -

SPES

Description of the supply

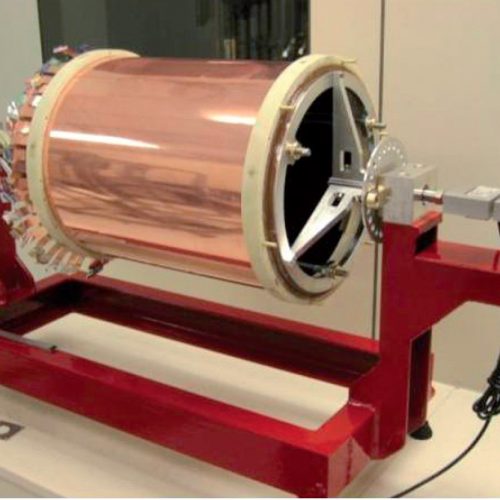

Supply was composed of:

• N° 5 Tanks in AISI 304L with closing caps and cooling channel fittings

• N° 1 Tank in AISI 316L with closing caps and cooling channel fittings

• N° 50 Shims for placing the modules on the final assembly

Each tank has an internal diameter of 754.14mm, which will then be electrodeposed with 0.07mm of copper.

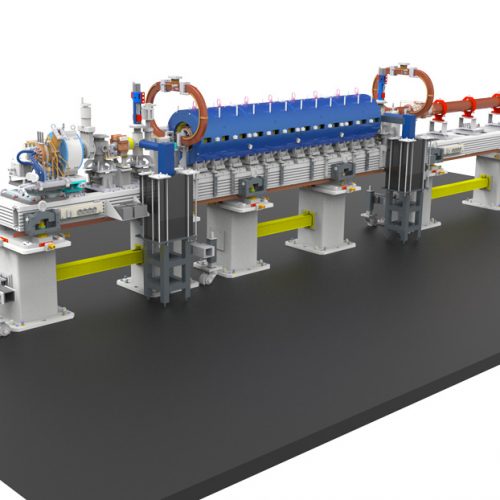

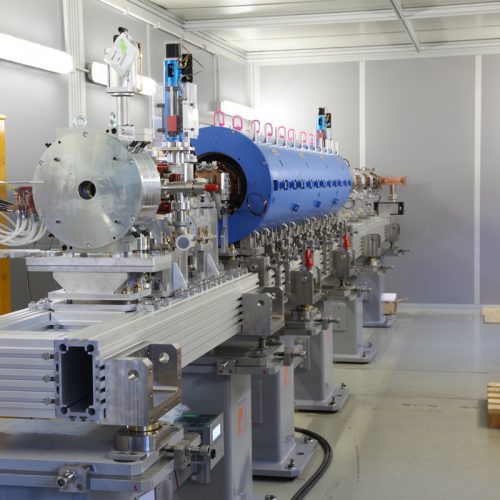

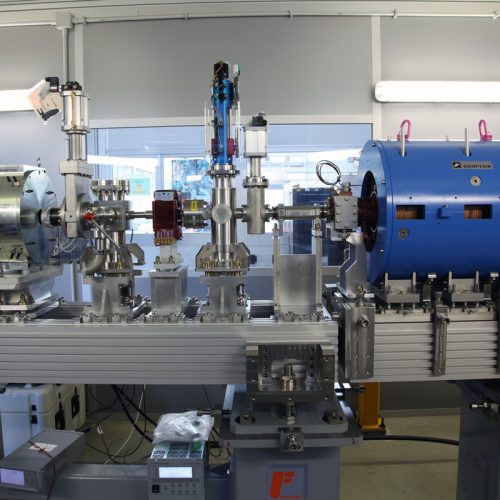

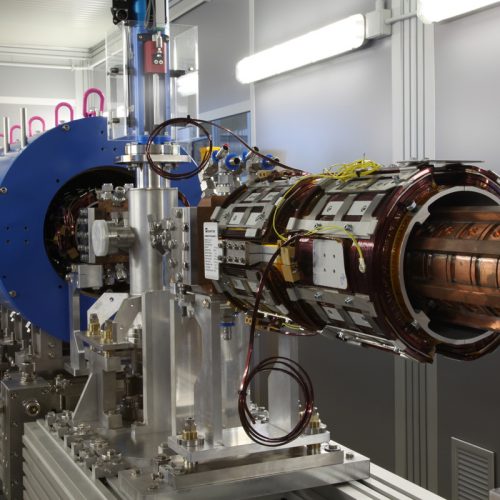

The operating pressure of the RFQ is 10⁻⁸mbar.Description of experiment

The SPES RFQ is designed in order to accelerate beams of exotic isotopesin CW with A/q ratios from 3 to 7.

The main goal of this project is to understand the origin of the elements in the Universe. This is a very ambitious and complex task that requires studying the characteristics of unstable (radioactive) nuclei through their decays and nuclear interactions of different types.

The SPES project, is based on the production of radioactive beams through the ISOL method, that is, through the impact of a high-intensity proton beam (energy of 40 MeV and current of 200 μA) on a direct UCx target. In this way, up to 10¹³ fissions per second can be produced by originating neutron-rich radioactive isotope beams that can reach intensities of 10⁹ particles per second on the target

The RFQ is composed of 6 modules about 1.2 m long each. Each module is basically composed of a AISI 304L SS Tank and four OFE Copper Electrodes (obtained by brazing of two subassemblies). A copper layer is plated on the tank inner surface and a spring joint between tank and electrode is used in order to seal the RF. -

THOR

Description of the supply

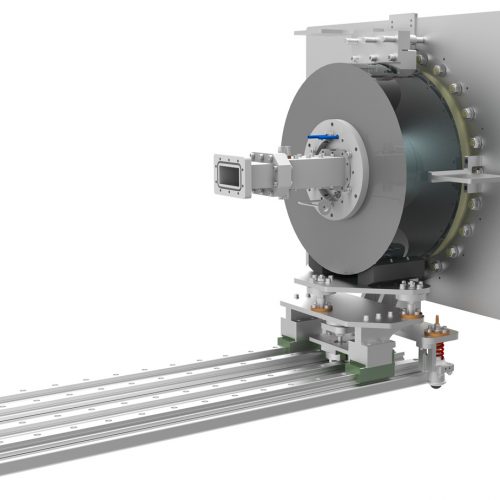

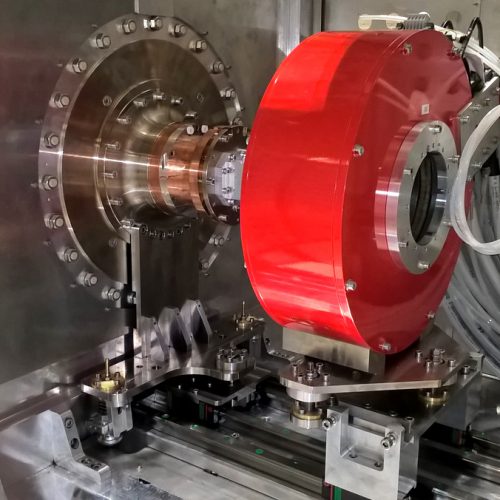

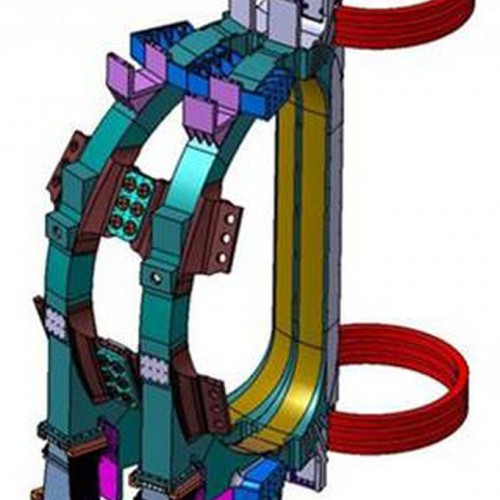

As part of the GSI-INFN collaboration, INFN is expected to support the testing of the magnets of the SIS100 accelerator at the FAIR facility (Facility for Antiproton and Ion Research, Darmstadt). The test line for FAIR’s SIS 100 accelerator quadrupole modules consists of in a system of coaxial cryostats which couple to the cryostat of the superconducting magnet module superconducting magnets module and manage its electrical and hydraulic connections to allow cooling at – 269°C.Description of experiment

The system consists of a Feed Box connected to the gas lines (hot and cold) and to the open cryostat of the module, an End Box on a mobile trolley for the rear closure of the horizontal cryostats, a central trolley for anchoring and positioning the quadrupole, a sliding track system approximately 9.5 metres long.

Horizontal Cryostat works in vacuum, at pressures P≈10⁻⁷ mbar, and with it both the Feed Box and the End Box share the same insulation vacuum. Therefore, the surfaces of these components are compatible with low pressure environments (UHV).

Intermediate temperature radiative shields in AW were covered with several layers of mylar aluminate (MLI) super-insulator, in order to adequately reduce the load due to the radiation.

He’s cryogenic flow circuits are located within the vacuum of the cryostats, so they must guarantee a tight seal to the outside: to this end, adequate pressure and vacuum tests have been provided to guarantee the tightness of the cryogenic circuits. -

SUPERCONDUCTING CYCLOTRON

Description of the supply

Fantini Sud has designed, manufactured and installed at the INFN-LNS Laboratories.

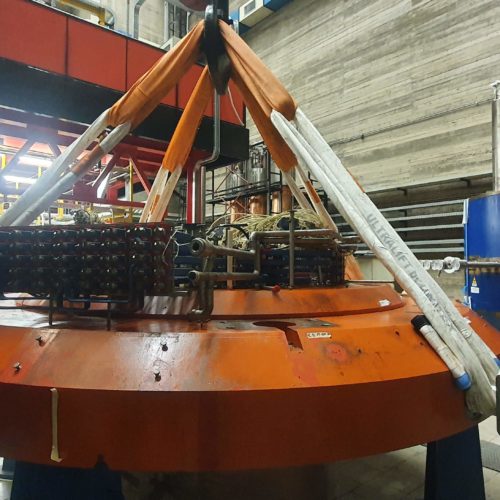

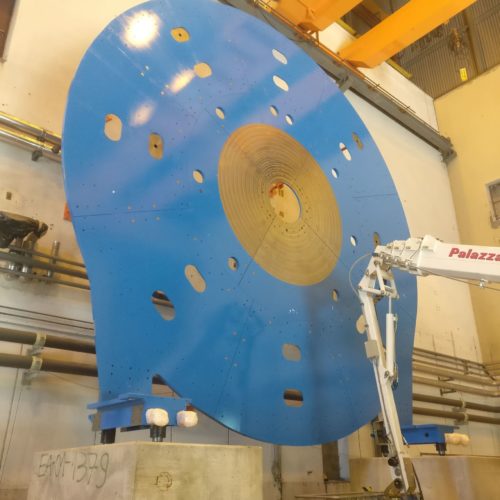

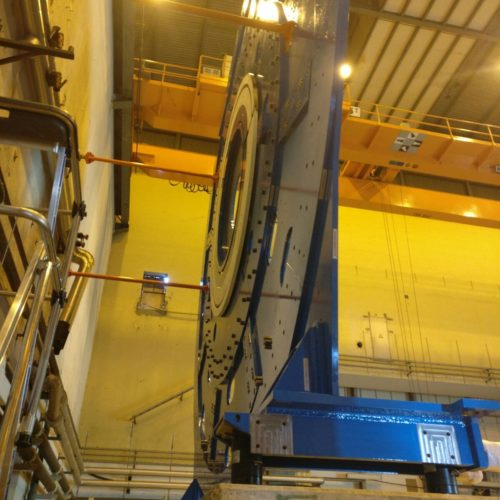

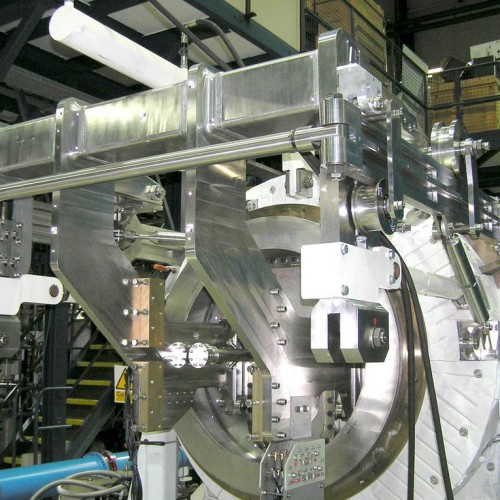

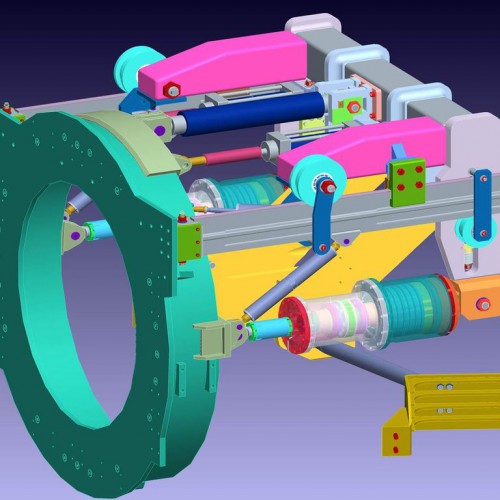

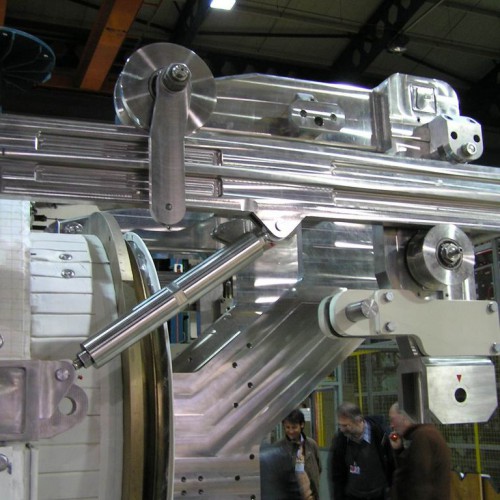

The function of the Tilter machine is to make the Upper Pole of the C.S. perform a complete tilt (180° around a horizontal axis) to allow operators, machining and assembly on both sides (while the Pole has a vertical axis) to upgrade the C.S. It is mainly made up of a fixed part, consisting of two Triangular Frames with the drives and two Crossbeams; a rotating assembly consisting of two Pole Grip Frames; and an Electrical Panel.

There are also two Sliding Platforms with their Support Frames; an Access Ladder; various Parapets.

The main characteristics of the product being handled are:

• external diameter of the Polo equal to 3806 mm;

• thickness of the heaviest part 540 mm;

• weight of the pole ~47.5tDescription of experiment

The ultimate goal of the project is to upgrade the research infrastructure of INFN-LNS, aimed at increasing the intensity, by about two orders of magnitude over the current maximum value, of ion beams with mass numbers below 40 and energies between 15 and 70 MeV/a.m.u., to be used in Nuclear Physics experiments for the study of rare phenomena. For this purpose, a Tilter machine was built for the rotation operations of the upper pole of the Superconducting Cyclotron located at the INFN-LNS Laboratories during the upgrade phases of the aforementioned accelerator machine.

Case History: Projects with ENEA

-

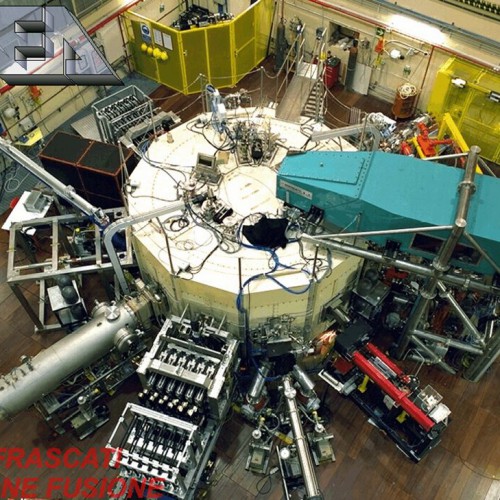

FTU

FTU is a medium scale tokamak with a 80,000 Gauss toroidal mechanical field. In order to generate such a strong magnetic field it is necessary to pass a current of 37,800 Ampère through the toroidal windings for a period of 1.5 seconds. Since all the FTU windings are copper reels, in order to avoid damaging them it is necessary to reduce their resistivity in order to reduce Joule effect dissipation drastically.

The only solution is to maintain them constantly at the temperature of liquid nitrogen: approximately -196 °C. Even though it is a medium scale tokamak, the FTU is a very complex device and requires a large number of systems (or sub-systems) in order to function correctly. This sub-assemblies, which are frequently very large, are physically installed in both the building that houses the “toro” (i.e. the central core consisting of the vacuum chamber and the toroidal and poloidal windings) and the various other buildings located around it.

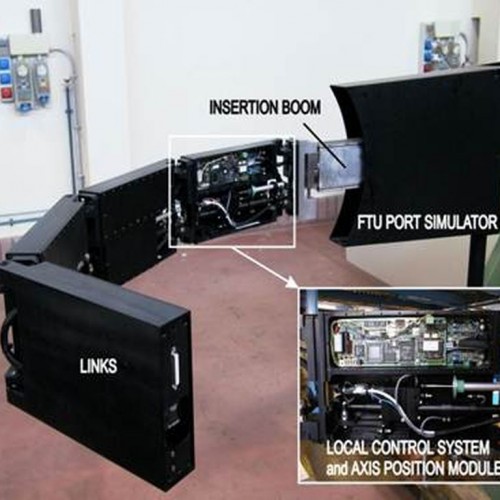

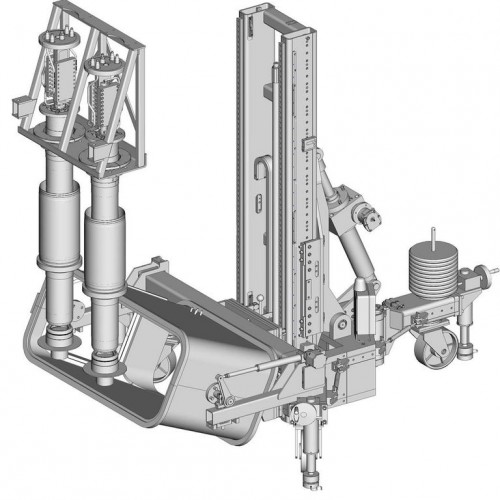

Two devices for remote handling on the Frascati Tokamak Upgrade machine (FTU) were produced for the ENEA Research Centre in Frascati (Rome).

IVROS – In Vessel Remote Operating System

This structure is used for dismantling the LIMITERs, i.e. the plates that form the internal protective layer on the walls of the fusion machine vacuum chamber. These plates may suffer localized damage in the event of a failure of the plasma magnetic confinement, in which case they must be removed and replaced.MULTI-LINK

This is a guide mounted, mobile structure designed to allow a manipulator, fitted with visual inspection tools and various instruments used to perform the measurements during the machine working life, to be introduced into the FTU chamber. -

FTU

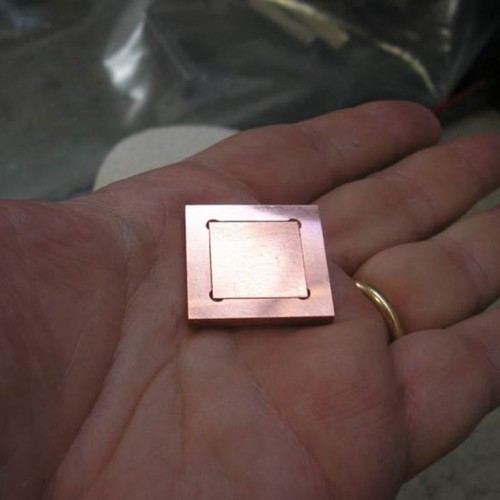

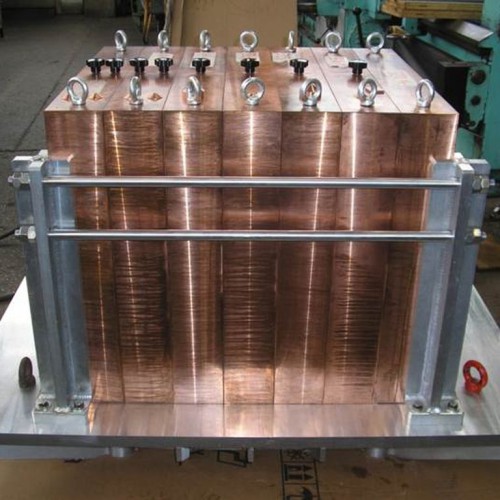

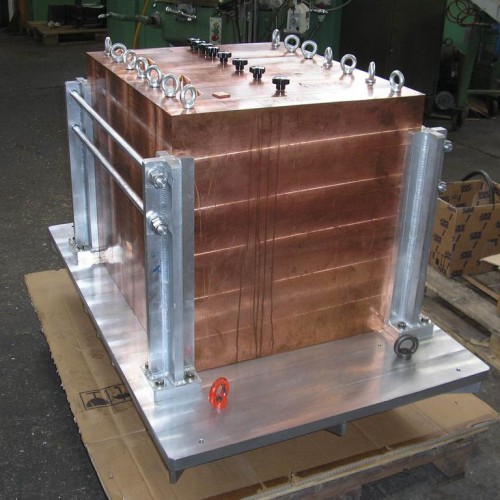

Multiple-layer target used for characterizing the interaction between OF electrolytic copper and neutrons in the nuclear fusion energy spectrum

The development of designs for the new prototypes of fusion reactors, of the type destined for the future production of electrical energy on an industrial scale, demands additional work on the physical and mechanical characteristics, the performance and the hardness of the necessary materials under the specific process conditions. This type of research is necessary because the physical and nuclear characteristics of the fusion reaction differ greatly to the characteristics of the various types of fission reactors, and because certain specific materials that were of little use in the nuclear power industry in the past are widely used in the development of fusion reactors.

This category includes electrolytic copper, which means that it is necessary to expand and extend our understanding of its characteristics in the interaction with neutrons in the energy spectrum of the generation of fusion reactors: neutronic absorption cross sections, tolerance to damage, durability, deviation of thermal and mechanical characteristics.

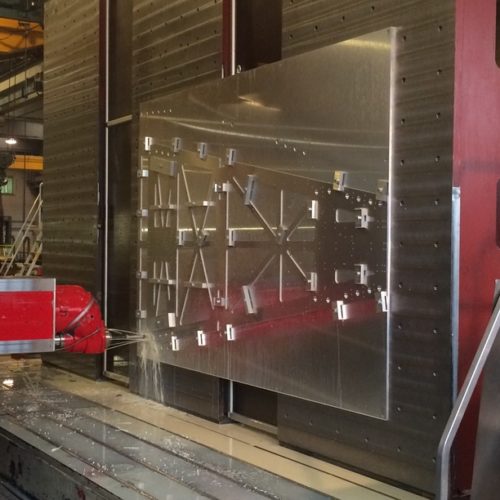

ENEA commissioned Fantini Sud to produce a multiple layer target weighing over 2,200 kg and constructed using 7 sheets of pure OF grade (Oxygen Free) electrolytic copper for a European research project; the sheets are supported by an aluminium frame suitable for installation on an adjustable structure.

Each sheet, which was manufactured in accordance with mechanical tolerances, houses a series of removable cylinders that contain the detectors used to measure the interaction between neutrons and copper; the accurate machining processes enabled us to reproduce the required geometry exactly as requested, thus eliminating the presence and disturbance of air within the test volume.

-

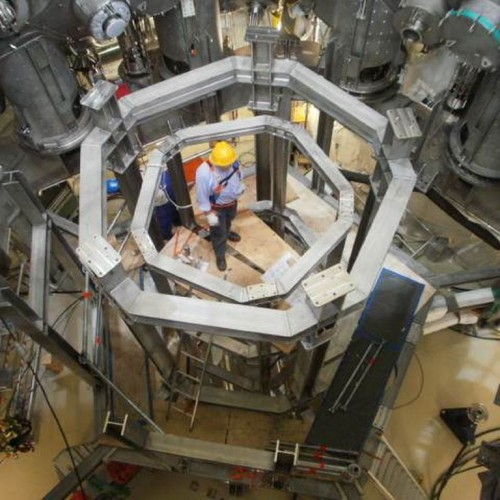

ITER RINGS

The pre-compression rings are destined to become one of the most stimulating composite structures ever produced. Weighing over 3 tonnes each, they will be used support the hanging weight of the ITER toroidal inductors, with a radial load of 7,000 tonnes per inductor, while also withstanding a hold-down stress of 350 MPa per ring.

Ten years of R&D at the ENEA laboratories in Frascati, in accordance with the agreements with the European Fusion Development Agency (EFDA), the European Domestic Agency and the direct contracts with the ITER organization, have culminated in a recent conclusion.

The work carried out by the ENEA team identified two suitable manufacturing processes for the rings and developed non-destructive examination methods using X-rays and ultrasound systems.The Italian team has also completed the mechanical characterization process on the fibre glass/epoxy composite at ambient and working temperature conditions, opening the way to the optimization of the final design of the ring, as well as determining the ultimate traction stress (UTS) of the 6 model rings (average value: 1500 MPa) using a specially designed machine that uses 18 independent hydraulic extractors to simulate the configuration of the 18 toroidal inductors.

ITER will be the largest tokamak (device used in the nuclear fusion process) ever built.

Fantini Sud has built the mechanical structure for the machine that will be used to perform the resistance and relaxation tests on the reduced scale ITER magnet compression rings.

Case History: Projects with GSI

-

TAF

Description of the supply

Two high-power lasers (Polaris and Jeti 200) are used at the Helmholtz Institute in Jena. The aim is to develop new types of energetic particles and light sources

The TAF chamber is powered with laser beams from the JETi 200 and POLARIS laser systems to perform experiments (e.g. electron acceleration). A vacuum <2*10⁻⁶ mbar is required to perform such experiments. Fantini Sud designed, manufactured and installed the TAF Vacuum Chamber at the Jena laboratory. Chamber has a welded modular load-bearing structure in AISI304L stainless steel, fully lined with access panels in 6082-T6 aluminium alloy. Vacuum Chamber TAF consists of 5 Frame connected together with Portal Flanges; its final dimensions are: 5816 x 2490 x 2470mm. In order to prevent deformation of the chamber frame caused by downward pumping, as well as the influences of vacuum pump vibrations on the sensitive optical assemblies on the breadboard, the breadboard was designed as a decoupled floor, the feet of which rest on a frame separated from the chamber by chamber bellows. To ensure maximum stability of the instrument support, the optical table and its independent structure have an inherent vibration frequency of more than 150 Hz, which resulted in extremely robust and massive components.

Case History: Projects with JULICH

-

NBPI

Description of the supply

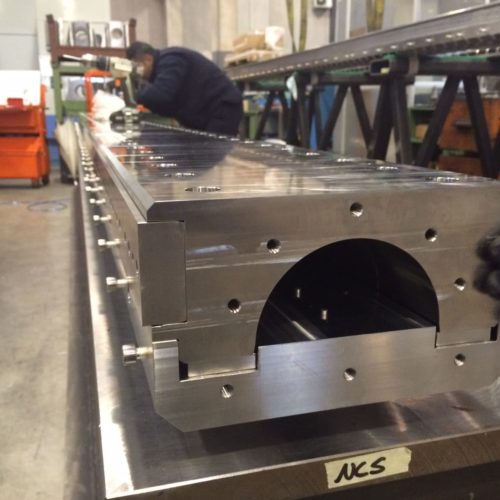

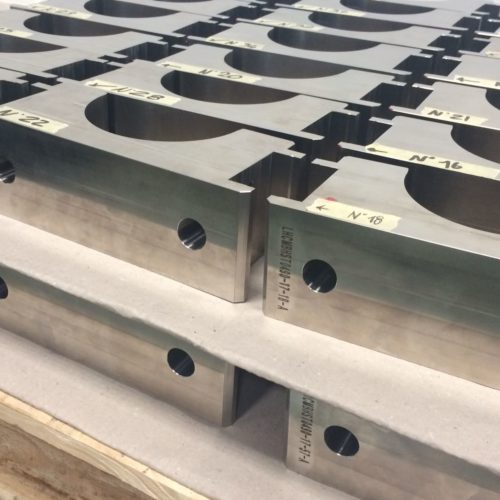

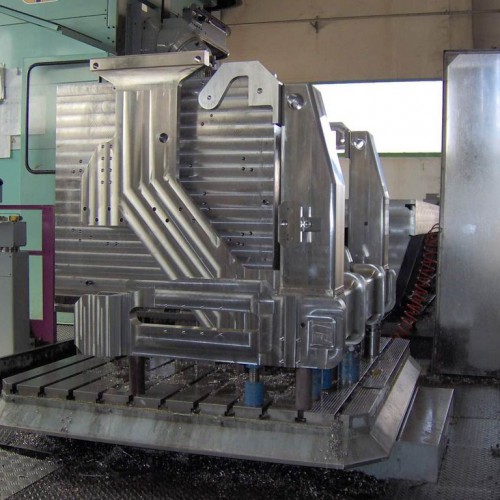

The monolith’s safety barrier is composed of several subsystems, one of which is the Neutron Beam Extraction System (NBEX), whose function is to guide the neutrons from the target to the final instrument station outside the bunker, where the experiments will be performed. The Neutron Beam Extraction System (NBEX), in turn, consists of several subsystems, such as the Neutron Beam Port Insert (NBPI).

Each NBPP is around 3.5 m long and weighs around 5 tons.

Each NBPI essentially consists of a base body and a lid which are milled. The neutrons enter through the front neutron window, are guided through the neutron guide (NBOA) and leave the NBPI through the rear neutron window in the direction of the end stations. The NBPI heats up as a result of the radiation. Therefore, two cooling systems are integrated in the modules to remove the heat, implemented through several deep-hole bores with a diameter of 10 mm in the base body.The peculiarity of the project provided by Fantini is that each NBPI is different from the other, especially regarding the depth of the channel.

NBPI project includes the manufacturing, cleaning, testing and the associated documentation as well as the packaging, intermediate storage and transport of a total of n° 16 NBPI to the ESS in Lund (Sweden). The raw material made of the material 1.4306 with a particularly low cobalt content (Co < 0.05 % based on the mass). The tightness requirements are as follows: • Maximum permissible total leak rate per NBPI: qi < 10-4mbar ∙ ls⁄ • Maximum permissible single leak rate per seal: qs < 10-6mbar ∙ ls All seals were checked for leakage and equal for the overall leakage rate. Leak tests were be performed using procedures A1 and A2 according to EN 1779.

Case History: Progetti con CERN

-

LHC

LHC – “Reaction Tool” device for the 11T DS Prototype Magnet

As part of the LHC (Large Hadron Collider) medium term development and expansion program, CERN is collaborating with FNAL (Fermi National Accelerator Laboratory in the USA) on the development of a superconducting dipole magnet with a very strong magnetic field, and a feasibility study on the application of Nb3Sn technology in very high energy fields.

In order to construct a 5.5 m long prototype Nb3Sn magnet, special molds are required for the superconductor core forming, heat treatment, impregnation, protection and manipulation processes.CERN commissioned Fantini Sud to produce the mold (Reaction Tool) to be used for the core forming and heat treatment phases. This high precision mechanical component consists of 145 stainless steel mechanical elements, which have been subjected to a vacuum stress-relief heat treatment cycle and machined according to extremely strict tolerances.

The various components have been designed to be fully interchangeable with the impregnation mold components so that they can be swapped between the two without subjecting the extremely delicate superconductor core to mechanical stress. -

LHC

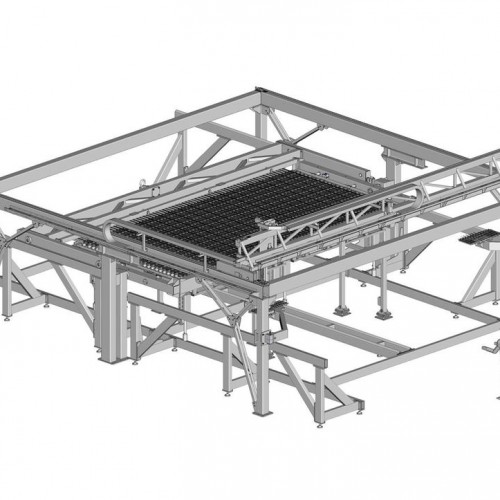

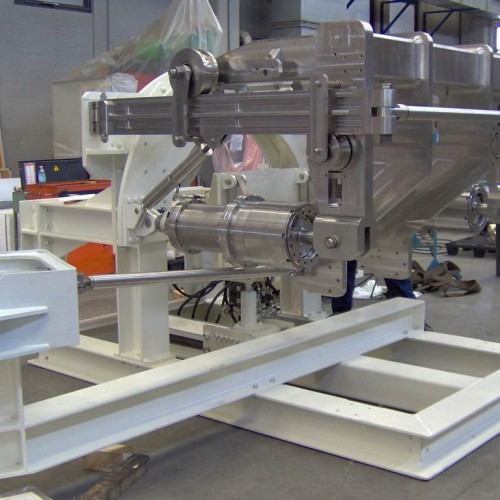

Assembly and manipulation bench for the 11T Magnet Prototype “Reaction Tool” and “Impregnation Tool” devices

The bench is a precision mechanical device specially designed for assembling and manipulating the forming and impregnation molds used for the 11T DS dipole magnet superconductor, developed by CERN in Geneva and FNAL (Fermi National Accelerator Laboratory in USA).CERN commissioned Fantini Sud to produce the bench, consisting of a servo-mechanism used to support, manipulate and rotate 6 metre long molds, and supported by an high rigidity base. It is designed for carrying out assembly and manipulation operations, as well as swapping elements between the two different formation and heat treatment (Reaction Tool) and resin impregnation (Impregnation Tool) molds, while ensuring the mechanical stress applied to the Nb3Sn semiconductor core remains within very strict limits.

Fantini Sud also produced the stainless steel “Reaction Tool” for CERN.

The bench is also used as an adjustable work station where intermediate operations such as inspections, laser measurements and depositing the fibre glass sheets on the core are carried out. -

HL-LHC

For CERN the company Fantini Sud has provided an assembly and rotation table for devices called “Reaction Tool” and “Impregnation Tool” for the 11T Prototype Magnet. The table is a precision mechanical apparatus expressly realized to support the activities related to the two molds of formation and impregnation of the superconducting nucleus of the dipole magnet 11T, result of the collaboration between the CERN of Geneva and the FNAL (Fermi National Accelerator Laboratory in USA) . This equipment is a servo-mechanism to support, manipulate and rotate molds 6 meters long, supported by a high rigidity base structure; it allows assembly operations, overturning and mutual permutation between the parts of the two different molds of formation and heat treatment (Reaction Tool) and impregnation with resin (Impregnation Tool), respecting stringent requirements for limiting mechanical stresses on the core semi-conductor in Nb3Sn.

-

HL-LHC

Description of the supply

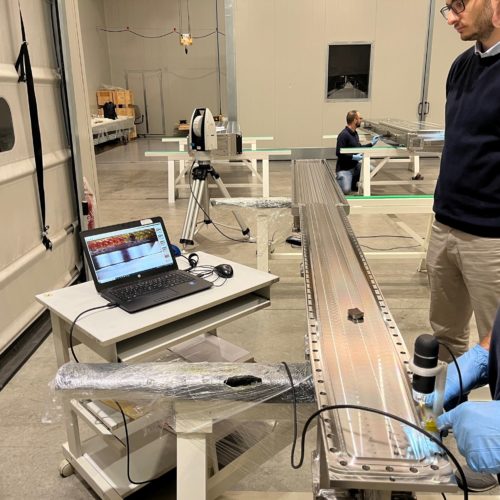

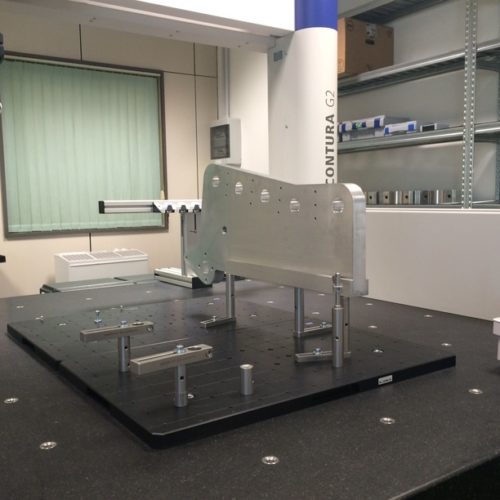

For CERN Fantini Sud has supplied numerous high precision mechanical parts for the assembly of a reaction device for the heat treatment of the Nb3Sn coils of the Tesla 11 magnet design. The parts realized were in stainless steel grade 1.4404 (AISI 316L).

Each part made was subjected to accurate dimensional checks, these dimensional inspections were carried out on a CMM measuring machine and some large components were measured using a Laser Tracker measurement system.Description of experiment

The Large Hadron Collider (LHC) is the most recent accelerator constructed on the CERN site. The LHC machine accelerates and collides proton beams but also heavier ions up to lead. It is installed in a 27 km circumference tunnel, about 100 m underground. The LHC design is based on superconducting twin-aperture cryo-magnets which operate in a superfluid helium bath at 1.9 K. High Luminosity LHC (HL-LHC) is a project aiming to upgrade the LHC collider in order to maintain scientific progress and exploit its full capacity.

Collimators are installed in the Large Hadron Collider (LHC) to intercept and absorb beam losses. In order to cope with intensities, which will be larger than nominal like in the High Luminosity LHC Project (HL-LHC), additional collimators will be installed in the Dispersion Suppressor (DS) regions of LHC at the location of selected 14.3 m long, 8.3 T Nb-Ti main bending dipoles (MB). Each concerned MB will be replaced by an 11 T dipole full assembly made of two 5.5 m long Nb3Sn 11 T dipole magnets, symmetrically installed around the centre of the replaced MB, and a bypass cryostat. -

ATLAS N.S.W. UPGRADE

Description of the supply

For CERN Fantini Sud has supplied a total of 24 mechanical assembly units, known as Central Spacer Frames, for the update of ATLAS New small wheel. The assembly unit is an equipment made of aluminum processed sheets with very precise interfaces of 45 mm thickness. The finished object has a size of about 4 meters x 2 meters and mainly includes parts made of standard aluminum alloy with some connection components made of stainless steel. The supply included 2 types of Spacer Frames, the type called “Small Sector Spacer Frames” and the type called “Large Sector Spacer Frames.” They are different only for their geometry but not for their functionality.Description of experiment

The goal of the New Small Wheel (NSW) Upgrade project of ATLAS is to replace the innermost station of the endcap muon system with new detectors during the next long shutdown in 2019/20. For particle detection, tracking and triggering, two different detector technologies will be used: MicroMesh Gaseous Structure (Micromegas, or MM) and Small strip Thin Gap Chambers (sTGC). Both are capable to operate under the high background rates expected during future LHC operation. Trapezoidal detector compound wedges (“NSW sectors”) of two sizes (“Large” and “Small” sectors) will be arranged on a wheel-like structure. The two new wheels have a disk geometry with a diameter of approximately 10 meters. -

ATLAS N.S.W. UPGRADE

Description of the supply

For CERN Fantini Sud has provided n. 2 disks of the new NJD DISK (one on the A side and one on the C side), which form a part of the mechanical support structure of the assembly of the New Small Wheel. NJD disk is a part of the mechanical structure of the New small wheel, its purpose is threefold: a) serves as a shield to the magnetic field detector due to product return from the field superconducting solenoid experiment, b) serves as a shield to the detector from radiation due to charged particles, c) provides mechanical support to the detector together with an aluminum structure bolted to it. The NJD disk is composed of individual elements machined in carbon steel. They are assembled in order to form a final disk-shaped assembly. The plates have a shape of circular sectors of different sizes and thicknesses. The NJD disk has a maximum diameter of almost 9 meters. The supply includes the following activities: The production of all components, the horizontal pre-assembly of each of the 2 NJD disks, the design, manufacture of auxiliary support structures for horizontal pre-assembly operations and finally the treatment surface and the protection of the identified surfaces.Description of experiment

The goal of the New Small Wheel (NSW) Upgrade project of ATLAS is to replace the innermost station of the endcap muon system with a new detector assembly during the next long shutdown in 2019/20. The new detector, as the present Small Wheel, has a disk geometry with a diameter of approximately 10 meters. For particle detection, tracking and triggering it uses two different detector technologies, MicroMesh Gaseous Structure (Micromegas) and Small strip Thin Gap Chambers (sTGC). Both are capable to operate under the high background rates expected during future LHC operation. A central part of each of the two New Small Wheels (one for side A and one for side C of the experiment) is the so-called NJD disk, made of structural steel plates

Case History: Projects with UKAEA

-

JET

As part of the European cooperation program for research activities into magnetic confinement fusion, the aim of the experimental project being carried out at the UKAEA (United Kingdom Atomic Energy Authority) Culham Science Centre JET (Joint European Torus) facility in Oxford is to demonstrate the technical and scientific feasibility of the production of energy from the fusion of light atoms.

The JET facility, for which the support structure for the antenna that will be used to heat the plasma by means of radio frequencies was produced, is a prototype machine built to the same scale as the future ITER machine; the latter, with a total power of approximately 500 MW, will be the first fusion machine to produce thermal energy in quantities comparable to a commercial reactor.

The structure produced for the JET facility was manufactured entirely in AISI 316 L stainless steel and consists of the following main elements:

- Trolley: a trolley with two attachments that the antenna will be mounted on.

- Guides and wheels: the trolley is fitted with two sets of wheels, one on each side, allowing it to compensate for the movements of the antenna, within certain limits, in the event of vibrations caused by disruptions in the plasma (impacts against the walls of the reaction chamber).

- N. 2 dampers designed to counter the force of the vacuum in the chamber where the antenna is installed.

- N. 2 pneumatic cylinders designed to counter variations in atmospheric pressure, within the limits +/- 10 Kn.

The system also includes a sling bar for moving the trolley/antenna assembly, and the equipment necessary to calibrate the dampers and the structure by simulating the forces that are applied during normal operation.

Case History: Projects with the MAX PLANCK INSTITUTE

-

W7 - X

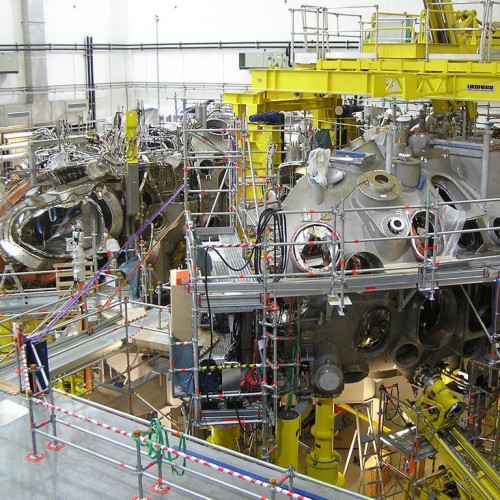

The Wendelstein-7X, constructed at the Max Planck Institute for Plasma Physics in Greifswald, in 2014 became the largest and most advanced Stellarator type reactor in the world.

The main aim of this project is to study the application of this configuration on future power generation plants. Optimization of the magnetic field generated by modular superconducting magnets will permit the W7-X to demonstrate the main feature of this machine: the capacity to operate on stationary state plasma.

-

W7 - X

The measurements carried out for the preparation of chamfers, manipulations and welding for the 254 Port (penetration in Plasma Vessels), required the production of the Ramps: specially designed mechanisms used to align the relevant masses accurately, manoeuvring within the reduced spaces available between the large number of systems already installed.

The Ramps, which are equipped with a freedom of movement of 10 or more degrees, and execute controlled movements in order to compensate for elastic deformation of the materials, can be used guide the Ports in any direction: supported by the Bridge above the W7-X; or suspended under the Outer Vessel on air bearings or wheels between the base, temporary structures and the Bus bars; or mounted on the Towers in case of the large ports in the equatorial zone.

The technical installation elements and the auxiliary equipment are currently tested using the delicate Current Lead prototypes, the high temperature superconductors (HTS) with the cold end at the top (in the case of the W7-X).

Additional techniques where the Ramps could be used to manipulate and install the Dome-Sections the bulky lower extensions of the Outer Vessel that will be installed after the Current Leads are currently under investigation.

English

English Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español Português

Português Türkçe

Türkçe