Technology

Products diversification and technological transfer between the company’s departments make up a remarkable competitive advantage of Fantini and the technological know-how is the supporting factor of this winning strategy. The continuous improvement and innovation of production processes allow Fantini to develop knowledge and references in high technology branches.

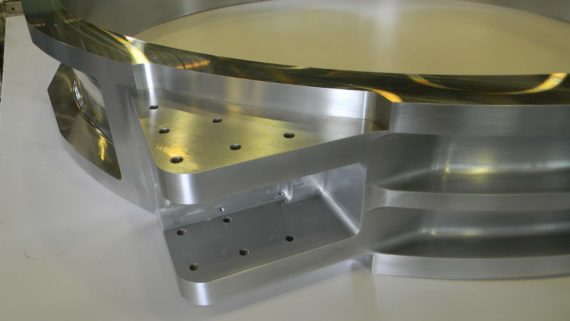

Precision Mechanical Components

Constantly updated machinery with advanced high-quality machines and most importantly, well trained and motivated staff with many years of engineering experience ensures accurate results. Fantini have one big workshop only for big CNC Machine specialized

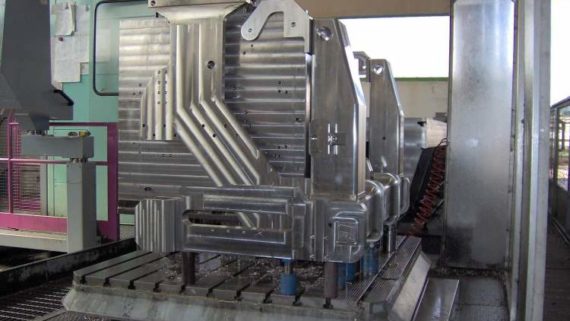

Large Mechanics

Constantly updated machinery with advanced high-quality machines and most importantly, well trained and motivated staff with many years of engineering experience ensures accurate results. Fantini have one big workshop only for big CNC Machine specialized for manufatcturing larger components with high precision.

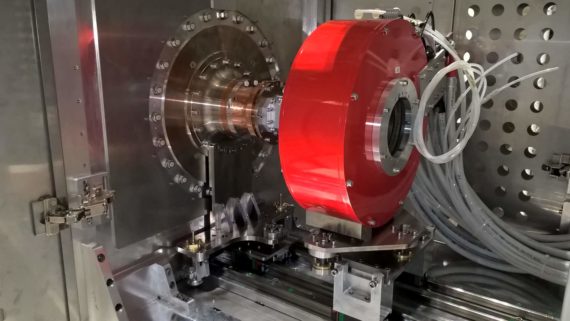

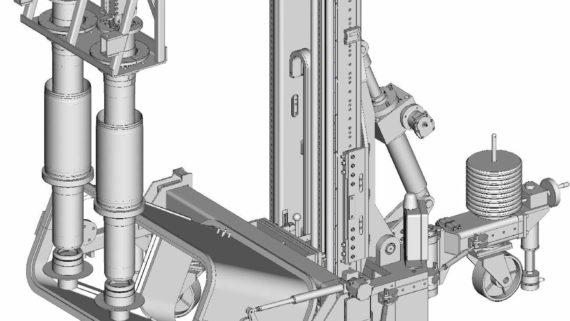

Mechanical Assembly & Testing

A lot of details and components are assembled together to create our products with the respect of test protocols and other documentation. Our fitters have years of experience in assembly and installation in a range of industries and research centres. Fantini perform installation at home and in the field of our customers. The training of customer personnel is also conducted if requested by the customer. Our assignments consist of turnkey solutions where we construct complete machines and special tools for different applications.

Surface Treatments

Fantini is capable of giving your components a particularly high surface quality. The following processes are available for this: Electropolishing, Polishing/manual finishing. The surface treatment serves besides optical effects to reduce outgassing or minimize the number of particles. We have specified processes with defined results for the surface treatment. If required, we are able to modify our processes for you to meet your requirements.

Clean Room/Area

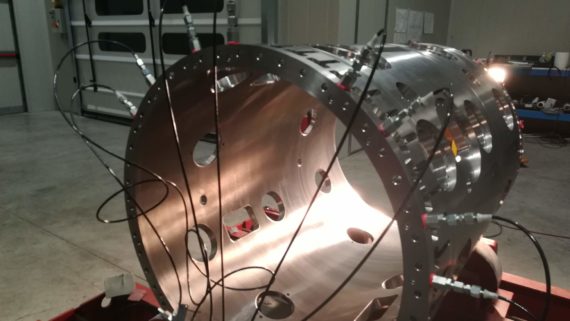

Fantini is capable to provides a cleanroom assembly service. To satisfy the customer’s expectations of clenliness, Fantini built a new clean area equipped with strumentation for vacuum technology and subject to stringent cleanliness regulations. In this clean area is possible to do vacuum test and metrological test for our vacuum chambers. Here is possible a leak test for continuos testing for final ispection, because products usually are exposed to high vacuum conditions, our quality assurance department has an experienced team that is capable of reliably testing vacuum components.

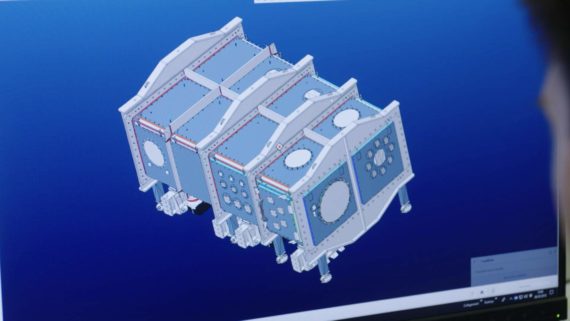

Design & Realization

Fantini’s development engineers have many years of extensive experience, particularly in the development of tailor-made mechanical systems and vacuum chambers. Thanks to costant new tasks, our technical department are familiar with applying new technologies, using new materials and combining then to meet the requirements of our customers in high-precision and cost-effective solutions. For analysis during the design phase and in order to replicate the behaviour of designed components, Fantini uses the finite element method (FEM).

Fantini can offer customized special vacuum chamber for accellerator technology and medical applications. Fantini offers a complete service package that covers everything from consulting, preparations and project planning, design and production, delivery, assembly to contractor’s site and reliable after-sales services. Fantini has a strong focus on high quality, flexibility and growth. Fantini builds large vacuum chambers made of stainless steel and aluminium, to assure the quality of these products the company increase every year the investments to obtaine quality, precision and testing for quality assurance.

English

English Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español Português

Português فارسی

فارسی