Production Departments

In order to guarantee our customers a rapid response to every issue regarding the production process, the Fantini Group has expanded over the years to include numerous production departments, featuring state-of-the-art machinery and highly skilled personnel. From plasma cutting systems to the assembly and functional test areas, we present our production departments:

Metal working & Welding

The department is divided into a series of manual welding lines where medium and large scale welded elements are prepared. The department also includes 4 automatic and semi-automatic band saws that are used to cut the commercial profiles and prepare the material for the welding operations material.

Plasma Cutting System

The cutting system uses plasma and Oxy-cutting technology cutting heads. The machine features a system for regulating the torch working height and numerical control that enables the operator to view a graphic display of the working plane and the cutting path. The system can be configured for a wide range of applications and guarantees high quality semi-finished products and excellent production efficiency.

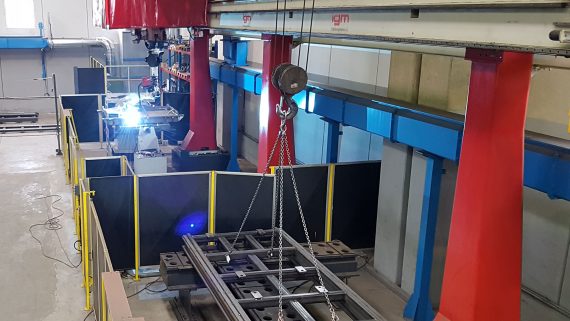

Automated Welding

The department is equipped with 2 automated welding stations. These stations feature anthropomorphic robot welding systems designed for increased productivity and high welding quality. Implementing this solution permits the Fantini production departments to block the components so that they are available for welding, thus automating the entire welding process.

The numerical control mechanical processing department is equipped with a large number of machine tools for processing medium and large scale components. The majority of the machines are moveable mounting milling machines with an effective stroke (X axis) equivalent to 12,000 mm, and horizontal work stations equipped with Multi-pallets for mounting and processing are range of different work-pieces, in accordance with the increasingly rigorous production requirements. The department also features a vertical lathe with a maximum turnable dimension equivalent to 3100 mm.

Machine Tools

The department where traditional mechanical machining work is carried out features a large number of machine tools for working small and medium scale components. In addition to traditional milling machines and parallel lathes, Fantini also boasts a series of hobbing machines, which are used for cutting the gears used in the production process.

Painting

At Fantini, the special painting process is carried out in booths designed to guarantee the quality and durability of the painting process. The technical specifications of the line ensure perfect visibility within the booths, which are equipped with a desiccation system that improves both the productivity and the end result of the painting process.

Among its numerous resources, the Fantini Group also boasts an electrical division where the electrical panels and machine electrical systems are produced. The division, is responsible for the entire process starting with the electrical design stage, is develops products that comply with the applicable standards and regulations and employs the latest technology and components wherever possible.

The Fantini Group includes a production facility dedicated exclusively to the assembly and function test phases for the lines produced by the machine division and the equipment and/or systems manufactured by the special divisions. A series of checks, designed to monitor and keep track of the most delicate stages of the Fantini product mounting operations, are carried out during the assembly phase.

Metrology

The Fantini group owns a measuring room with constant and controlled temperature and humidity, with built in reporting on the evolution of environmental variables. Inside, in addition to primary samples with traceability guaranteed by legally recognized institutions at national and international level, there is a CMM gantry measuring machine for the measurement of shapes and surfaces of articles up to: X 1000; Y 1200; Z 600, with a measurement margin of error of 1.5 + L / 350 microns.

English

English Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español Português

Português Türkçe

Türkçe فارسی

فارسی